PRODUCTION INFORMATION

Production Description

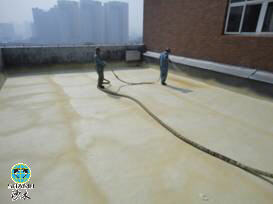

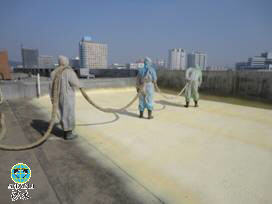

Qtech-300 Roof Insulation & Water Proofing Polyurethane is the state of the art two components polyurethane foam. The system consists of A component, organic diisocyanate, and B component, dihydroxy or polyol. Qtech-300 is used by itself or in combination with polyurea for roof insulation and water proofing. Qtech-300 can produce extremely rigid foams at all thicknesses; it may be applied in all positions and to any suitably prepared substrate. Qtech-300 is a great material which has excellent efficiency on roof insulation and water proofing; it will achieve better protection system by combining polyurethane with polyurea to form an integral waterproofing and insulation roofing system.

Advantages

1. Light specific gravity, high strength, reduce the load of the roof.

2. High density closed-cell foam, good energy-saving effect, the heat conductivity is no more than 0.022W/mk.

3. High compressive strength(≥0.3MPa), the maximum be may be 0.6MPa in practice.

4. Green non-polluting, environment-friendly.

5. Good impermeability resistance, can form an seamless and continuous shells on roof.

6. Mechanized construction, can be applied on any complicated substrate.

7. Heat insulation, water proofing and aging resistance.

8. Adhesive to concrete, wood and metal.

9. Seamless, flexible, slick and non-porous.

10. No need of prefabrication or joint process; can be produce and applied at the same time..

Recommended Uses

Qtech-300 Roof Insulation & Water Proofing Polyurethane, combining two functions of heat insulation and water proof together, has high elasticity and strength, it can be widely used in roof insulation, roof insulation and water proofing of external walls, thermal insulation for pipelines, building board, refrigerator wagon and refrigerator etc.

Physical Properties

|

Compression Strength/(MPa)

|

0.2

|

|

Compressive Strength/ (MPa)

|

≤0.15

|

|

Product Characteristics

|

Density/(Kg/m3)

|

≥35

|

|

Heat Conductivity/(W/(m•k))

|

≤0.024

|

|

Porosity by Closed Pore/%

|

≥90

|

|

Water Absorption/(Kg/m2)

|

≤0.2

|

|

Melting Point/ ºC

|

170~190

|

|

Oxygen Index/%

|

≥26

|

|

Colors

|

Optional

|

|

Tack Free/s

|

60

|

|

Shelf Life

|

6 months, unopened at 15-40 ºC

|

|

Recommended Thickness/mm

|

3-7

|

|

Colors

|

Optional

|

|

Drying time is temperature, humidity, and film thickness dependent.

Substrate requirement

Surface should be stuff and smooth , puffy and swollen should be removed and leveling with mortar.

Remove all dirt, grease, oil, contamination, etc. by mechanical methods such as sandblasting or shotblasting are preferred.

The water content of substrate should less than 7%, route and seal all cracks with proper surface preparation system.

Installation

Consult our application information and recommended method statements.

Packaging

• Part A: 220kilogram per drums.

• Part B: 200 kilogram per drums.

( Custom package available at additional charge).

Notes

1. Application ambient temperature must above 15 ℃, the wind should less than Beaufot-scale 4, not recommend application when rainy, high moisture, and frost and dew day.

2. Qtech product is intended for industrial use by properly trained professional applicators only.

3. Thoroughly mix container of B component with an air-driven power mixer for a minimum of 15 minutes prior to application.

4. Adding a nitrogen blanket is strongly recommended for use on the “A” component for storage after opening.

5. Detail processing such as corner, window and door required installed pre spray application, avoiding contamination, thickness each spraying should be 10~15mm.

6. It is a 100% solids production, strictly prohibit add any diluents.

7. The quality and fitness of the product is depending upon the proper mixture and application of the component by the applicator.

8. This specification is an accumulation of long term testing and experience. Published technical data and instructions are subject to change without notice.

Technical Data Sheets

• Qtech-300 Roof Insulation & Water Proofing Polyurethane  [2011-05-06]

[2011-05-06]

![]() [2011-05-06]

[2011-05-06]