QTECH-407 was applied on the Water Diversion Project

Published:2016-03-03 Source:ShaMu international View:1378

The middle line of Water Diversion Project, begins from the east coast of Danjiangkou reservoir, passes though Fangcheng bealock of Yangtze river basin and Huai River basin, excavate channels along the White River basin and west coast of the Huanghuaihai plain, passing through the tunnel to the yellow river around Zhengzhou city Henan province, point to the north along Beijing-Guangzhou railway, then flow to the Round City lake of the Summer Palace in Beijing . The main water supply area is Tangbai River plain and the middle west of Huanghuaihe plain, the water supply area is 155000km2, the overall length of the main canal of the middle line is about 1277 km, the main canal to Tianjin is 154km.

This project can ease the crisis of water resources of Beijing, Tianjin and the North China, and greatly improve the ecological environment and investment environment around this area, in order to promote economic development of the Middle China, which is a significant ecological project, economic project and social project.

In order to reduce lose of the water,

Prof. Huang of Qingdao Technological University was invited by the Construction Authority of the middle line of Water Diversion Project, and attended the “expert consultation of the first stage middle line project of Water Diversion project on the seepage-proofing problems of the inside of the main channel sand river aqueduct project” at Ping Dingshan city Henan province, to help the experts and leaders of this project to identify the pure polyurea and the fake one, and how to test the mechanical property and the drinking water safety performance of polyurea in the jobsite, in order to insure the safety, reliability and durability of aqueduct, closed conduit and open conduit of Water Diversion Project-------the national key infrastructure projects.

|

|

|

|

Jobsite investigation of Prof. Huang and the engineers |

After the comprehensive evaluation of the headquarters and proprietors, our “Qtech-407 Anti-Microbial Polyurea Material” stands out of all the other “polyurea”. Qtech-407has pass the Safety Evaluation Stander of the carriage and distribution devices of potable water” (GB/T17219-1998)(

2012-09-25 ), and was successfully been applied on Qingdao Shuyuan reservoir canal in 2011. The construction just during the Tomb-sweeping day, but we send the technicians immediately to the jobsite, and provide the best technical support and service for the project.

As it was always claimed by

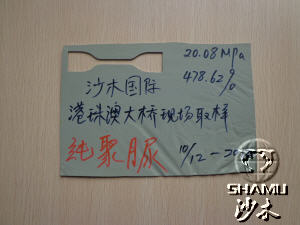

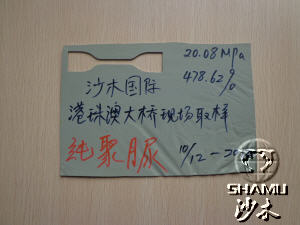

Prof. Huang, we sprayed and take the sample at the jobsite when the proprietor, supervisor, constructor and our technicians were all in the jobsite, after testing by the Institute of Functional Material of Qingdao Technological University, the result shows that, the tensile strength is 20.61Mpa, and the elongation at break is 429.92%, it doesn’t pass the requirement of National Standard GB/T23446-2009 as the elongation at break should be higher than 450%, and it is also lower than the testing result of the sample of Hongkong-Zhuhai-Macau bridge, the tensile strength is 20.61 MPa and the elongation at break is 478.62%(

2012-11-26 ).The reason is that the constructor didn’t use the drying tube and the water separator, which cause much micropore in the fracture surface of the polyurea, Now, our technicians had instructed the constructor to add all the required equipments, and should follow the instrument of QTG training to standardize the construction, try the best to insure the quality of the national key project.

|

|

|

|

Befor spray |

After spray |

During spray |

|

|

|

Sample in the Water Diversion Project |

Sample in the Hongkong-Zhuhai-Macau Project |

|

|

|

Shamu Technician guide the Substrate preparation |

Shamu Technician guide polyurea spray |